Contact: Miss Zhang

Phone: 13829131365

Mail: cnfuxinde@163.com

Web:www.fxdcleanroom.com

Add: No. 3 Yuanying Road, Liaobu Town, Dongguan City, Guangdong Province

Definition of clean room:

Clean Room is also called clean workshop, dust-free workshop and dust-free room. It means removing particulates, harmful air, bacteria and other pollutants from the air in a certain space, and controlling the temperature, cleanliness, indoor pressure, airflow velocity and airflow distribution, noise, vibration, lighting and static electricity in a certain need. Within the scope of the request, the room is specially designed. That is to say, no matter how the external air conditions change, its indoor performance can maintain the cleanliness, temperature, humidity and pressure required previously. Widely used in semiconductor, microelectronics, PCB, photoelectric technology, optical instruments, biological engineering, medical and health, fine chemicals and food industry and other high-tech fields to provide a clean production environment of grade 10-300,000.

Material requirements:

The building decoration of the clean room has a direct impact on the comprehensive performance of the clean room. Therefore, the requirements are: smooth surface, wear resistance, non-static electricity, non-moisture absorption, non-dust production of materials, non-dust accumulation (structure), non-dust permeability (tightness), ground wear resistance, corrosion resistance, anti-static electricity, anti-skid, easy cleaning.

Structural materials:

1. Clean workshop paint and roof materials are usually made of 50 mm thick sandwich color steel plate, which is characterized by beautiful appearance and strong rigidity. Arc corner, doors, window frames, etc. are generally made of special alumina profiles.

2. Epoxy self-flowing floor or high-grade wear-resistant plastic floor can be used on the ground. Anti-static type can be selected if there is anti-static requirement.

3. The air supply and return pipeline is made of hot-dipped zinc sheet, which has good purification and thermal insulation effect with flame-retardant PEF thermal insulation material.

4. The high-efficiency air outlet adopts stainless steel frame or spray-moulded frame, which is beautiful and clean, rust-free and dust-free, and easy to clean.

Classification of clean rooms:

By use:

A. Industrial cleanroom (inanimate particulate matter as control object)

B. Biological clean room (with living particles as control object)

According to the air flow, it can be divided into:

A. Non-unidirectional flow clean rooms (chaotic clean rooms)

The principle of non-unidirectional flow clean room is dilution. When a clean air stream is sent into the room from the air supply port, it quickly diffuses and mixes around. At the same time, almost the same amount of air flow is discharged from the return air outlet. This clean air flow dilutes the indoor polluted air and dilutes the indoor air with high dust concentration until it reaches equilibrium. So the faster and more uniform the airflow diffuses, the better the dilution effect of course.

B. One-way flow clean room

Characteristics of one-way flow clean room:

(1) The flow velocity on the section of the whole chamber is relatively uniform.

(2) Streamlines are parallel in the working area. Streamline parallelism refers to the time-averaged streamlines being parallel to each other.

(3) There is no eddy current in the working area.

Classification of one-way flow clean rooms:

1. Vertical one-way flow clean room

(1) The roof is covered with high efficiency filters and the floor is covered with grilles. This is a typical vertical one-way flow clean room. See Figure 1.

Advantages: Unidirectional downward air flow can be obtained, which has strong self-purification ability and can achieve the highest cleanliness level.

(2) Side cloth high efficiency filter roof damper layer air supply, full floor grille return air.

(3) Double-cloth high-efficiency filter air supply on the roof and side, and full-floor grille return air.

(4) Full-roof air supply and downward air return on both sides.

2. Horizontal one-way flow clean room

(1) The air supply wall is full of high efficiency filters for horizontal air supply and full wall air return, as shown in Figure 2.

(2) Tunnel-type one-way air supply

Design features:

Decoration section:

All the walls and ceilings in the clean area are made of stainless steel, arc corner transition is used at the corner, and all the doors (stainless steel doors) and windows (glass windows) of the clean workshop are made of special aluminium alloy frame, which ensures good sealing performance and aesthetic effect of the workshop; the floor of the production workshop is made of stainless steel or aluminium alloy elevated floors, and it is easy to produce dust. Clean, to ensure a good clean environment in the workshop.

Purification section:

The air flow organization scheme of upper feeding and lower feeding side return is adopted, and the air conditioning unit with full automatic constant temperature and humidity air conditioning unit + medium efficiency Booster Box + high efficiency air outlet combination is used for air conditioning to ensure good cleanliness. The air conditioning air supply system is filtered by primary, middle and high stages, and the filtration efficiency of high efficiency filter is 99.99%. Personnel need to go through four steps of "changing shoes changing clothes buffering air shower" to enter the clean area.

Electrical part:

Lighting lamps and lanterns are equipped with special cleaning lamps for clean rooms, some of them with emergency power supply can be extinguished with 30 minutes delay in power outage in factories. When power outage suddenly occurs in factories, they can have certain illumination for emergency treatment of production equipment and evacuation of clean room workers. Power distribution sockets are divided into 380V, 220V and 36V forms. On the ground, all the lines are hidden under the floor.

Design features:

Decoration section:

All walls and ceilings in the clean area are made of coloured steel plates, arc and corner transition are used, all doors in the clean workshop are made of stainless steel frame fully automatic induction cleaning doors, and observation windows are made of aluminium alloy frame cleaning glass windows to ensure good sealing performance and aesthetic effect of the workshop; EPOXY and PVC anti-static ground are laid on the floor of the production workshop. Plate, dust-free and easy to clean, put a 100-level clean table production line, to ensure the cleanliness of production process and production process requirements.

Purification section:

The air-conditioning system adopts the air-flow organization scheme of up-feed and down-return, and adopts the combination of "water cooler + humidifier + medium-efficiency booster + high-efficiency air outlet" to carry out air conditioning, which guarantees good cleanliness without the expensive cost of constant temperature and humidity air conditioners; the air-conditioning air-supply system has been filtered by primary, middle and high-level filters, and the high-efficiency filters have passed through. The filtering effect is 9.

Electrical part:

Lighting lamps and lanterns are equipped with special cleaning lamps for clean rooms, some of them are equipped with emergency power supply; they can be extinguished after 30 minutes of power failure in factories; when power failure suddenly occurs in factories, they can have certain illumination to deal with emergency production equipment and evacuate workers in clean rooms; all power wiring of 100-grade clean workbenches are laid in dark.

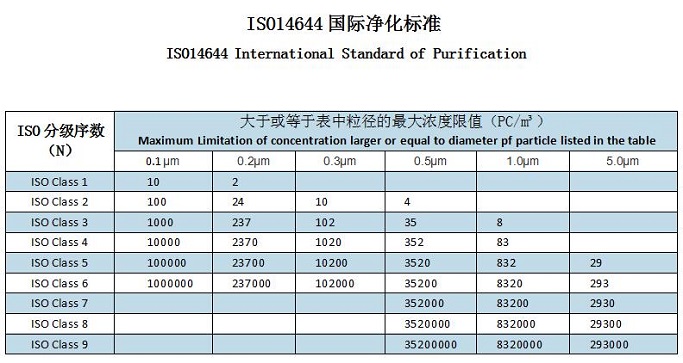

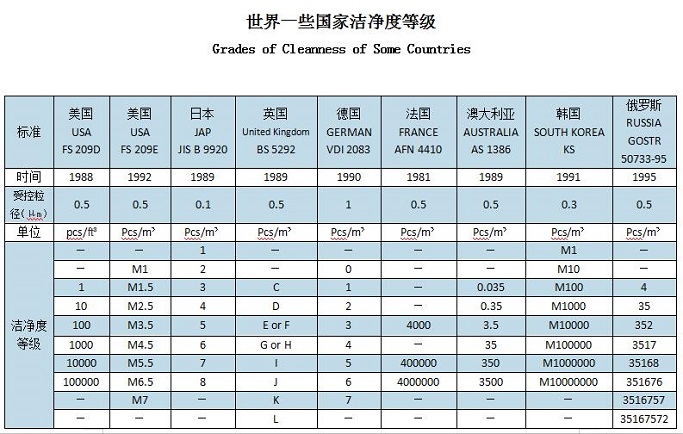

Cleanliness Classification Standard (commonly used):